Don't get a half-baked temperature monitoring system

Originally published - October 9, 2019

Updated and republished - March 16, 2022

Setting up a lab with new equipment can be fun and nerve-wracking at the same time. On the one hand, it’s exciting to have new toys; on the other hand you have to justify the need, cost, space, etc. for the new toys that you want. One of the most important but overlooked pieces of equipment a lab has is cold storage, such as ultralow temperature freezers. From the outside, they may look like they are sitting idle, but in reality, they are running 24/7 preserving and maintaining the integrity of the precious samples and materials that they house.

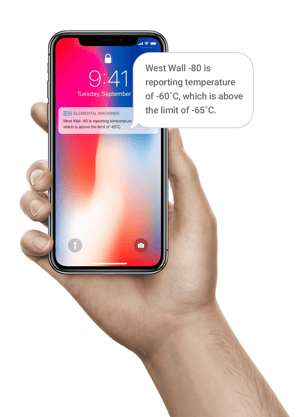

Because of that, there are several things to take into consideration when making purchasing and operational decisions for your new ultralow temperature freezers, such as temperature regulation (obviously), equipment footprint, maintenance logistics, and most importantly temperature monitoring. Freezers often come with built-in temperature monitoring, but these are simplistic solutions with limited usefulness. An audible alarm can go off when the temperature within a cold storage unit exceeds specified thresholds. This is only useful if someone is in the vicinity of the freezer, actually hears the alarm, and addresses the issue. But what happens when someone isn’t nearby, such as during evening and weekend hours?

Equipment monitoring & alerting

“That’s when a comprehensive monitoring solution comes in really handy and delivers alarms via text message to a variety of team members during power outages, internet outages, etc.” says Elemental Machines CEO Sridhar Iyengar. But that’s not all a comprehensive temperature monitoring solution can offer. With an Element-T unit collecting temperature data every 15 seconds, laboratory teams are able to glean so much more information. For example, the data we collect gives us insight on when a freezer may need to be defrosted or may imminently fail. How do we do it? To find out, read the full interview with Sridhar Iyengar in Biocompare.

“That’s when a comprehensive monitoring solution comes in really handy and delivers alarms via text message to a variety of team members during power outages, internet outages, etc.” says Elemental Machines CEO Sridhar Iyengar. But that’s not all a comprehensive temperature monitoring solution can offer. With an Element-T unit collecting temperature data every 15 seconds, laboratory teams are able to glean so much more information. For example, the data we collect gives us insight on when a freezer may need to be defrosted or may imminently fail. How do we do it? To find out, read the full interview with Sridhar Iyengar in Biocompare.

Equipment utilization

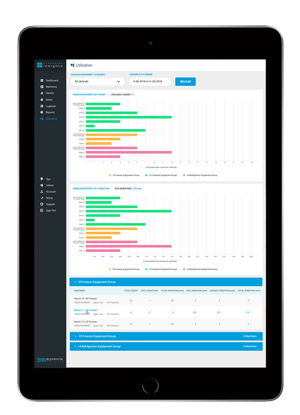

Another benefit of a comprehensive monitoring solution is insights on equipment utilization. For organizations that maintain freezer farms of over 100 freezers, questions arise:

- Are they all being used?

- Are some freezers doors never opened?

- Could the lab be saving money by decommissioning some unused freezers?

Interestingly, Elemental Machines did a study with one of our customers and found that two of the freezers at their site were never opened over a two-month period. It may not seem like a lot, but when you factor in maintenance costs and lab space, the annual cost can be as high as $26,000.

In a more recent large pharma example, utilization monitoring of 20 devices for 30 days on the Elemental Machines platform resulted in customer savings of $40,000 through a combination of asset decommissioning and corresponding service plans and warranties.

Cloud-based, user-friendly system

With such a comprehensive system, one may be intimidated that this may be a very complex platform to maneuver. Quite the contrary! The platform is a battery-operated wireless system that does not require any mounting screws. Instead, the magnets inside the Element-T devices allow easy fixture to the metallic surfaces of any freezer or refrigerator. The Element-T's thermocouple wire used for the temperature measurement is very thin (~500 micron) so it does not interfere with the door seal. Element-T units can be used on both older and new freezers, making scalability easy. In fact, all installs can be up and running within minutes.

The battery-operated Element-U can be easily installed onto most equipment cables, without any tools, in less than one minute. Utilization monitoring can easily be expanded with the addition of additional Element-U devices. Element-U units can be installed one-handed in space where cables are hard to reach and can accommodate large cable sizes, to ensure every asset in the lab can be monitored.

Data collected from Element-T and Element-U devices is uploaded onto the Elemental Cloud for user review - anytime, anywhere. Care to learn more? Request a demo here!

Never miss a beat...

Subscribe to our bi-monthly EM Connect Newsletter to stay up-to-date on all things LabOps, biotech, and more!